Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

In the fast-paced world of technology, data cables play a crucial role in ensuring seamless connectivity and efficient data transfer. Among the leading manufacturers in this field, the TPE injection data cable company stands out for its innovation and quality. This blog delves into the various aspects of TPE injection data cables, their manufacturing process, and why choosing a TPE injection data cable company can be a game-changer for your connectivity needs.

What is TPE Injection?

Understanding TPE

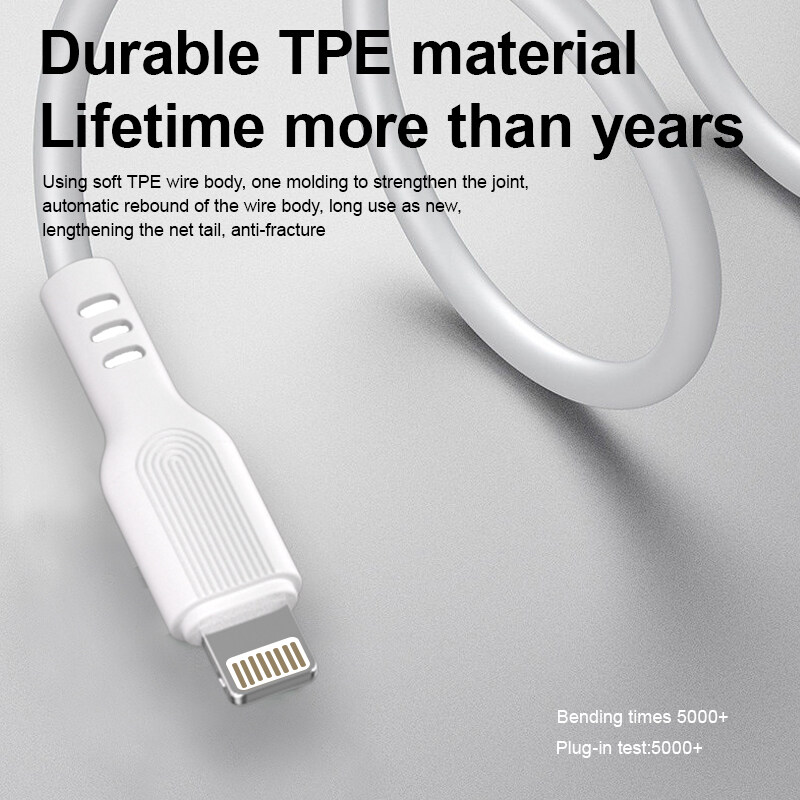

Thermoplastic Elastomer (TPE) is a versatile material that combines the elasticity of rubber with the processability of plastics. TPE is used in various applications due to its flexibility, durability, and ease of manufacturing.

The Injection Molding Process

TPE injection molding is a process where TPE material is melted and injected into a mold to form the desired shape. This method is highly efficient and allows for the production of intricate and consistent designs. The TPE injection data cable company uses this technology to produce high-quality data cables that meet the demands of modern connectivity.

Advantages of TPE Injection Data Cables

Durability and Flexibility

One of the main reasons to choose a company is the durability and flexibility of their products. TPE cables are known for their resistance to wear and tear, making them ideal for everyday use. They can withstand bending, twisting, and stretching without compromising their performance.

Environmental Benefits

TPE is a recyclable material, making it an eco-friendly choice. By opting for products from a company, consumers contribute to reducing environmental impact. These cables can be reprocessed and reused, aligning with sustainable practices.

Superior Performance

Cables produced by a company are designed to deliver superior performance. They offer excellent electrical insulation, which ensures stable and efficient data transfer. Whether for charging devices or transferring data, these cables provide reliable connectivity.

The Manufacturing Excellence of TPE Injection Data Cable Companies

State-of-the-Art Facilities

A leading company invests in state-of-the-art manufacturing facilities. These facilities are equipped with advanced machinery and technology that allow for precision and consistency in production. The controlled environment ensures that each cable meets stringent quality standards.

Quality Control

Quality control is a critical aspect of the manufacturing process for any company. Rigorous testing is conducted at various stages of production to ensure that each cable performs optimally. This includes tests for durability, conductivity, and flexibility.

Innovation and Research

Continuous innovation is at the heart of a top TPE injection data cable company. Investing in research and development allows these companies to stay ahead of the curve. By exploring new materials and production techniques, they can introduce innovative products that meet evolving consumer needs.

Applications of TPE Injection Data Cables

Consumer Electronics

TPE injection data cables are widely used in consumer electronics, including smartphones, tablets, and laptops. Their durability and flexibility make them ideal for daily use, ensuring that devices stay charged and data transfers remain uninterrupted.

Industrial Use

In industrial settings, TPE injection data cables are valued for their robustness and reliability. They can withstand harsh environments, making them suitable for use in machinery and equipment that require consistent and stable connectivity.

Automotive Industry

The automotive industry also benefits from the advanced capabilities of TPE injection data cables. These cables are used in various components, including infotainment systems, sensors, and other electronic devices within vehicles.

Choosing the Right TPE Injection Data Cable Company

Reputation and Experience

When selecting a company, it is crucial to consider their reputation and experience. A company with a proven track record of delivering high-quality products is more likely to meet your needs and expectations.

Product Range

A diverse product range is another factor to consider. A reputable company will offer a wide variety of cables to cater to different applications and requirements. This ensures that you can find the right cable for your specific needs.

Customer Support

Excellent customer support is essential when dealing with technical products. Choose a company that provides comprehensive customer service, including technical support and after-sales assistance. This ensures that any issues are promptly addressed, and you can get the most out of your purchase.

The Future of TPE Injection Data Cables

Advancements in Material Science

The future of TPE injection data cables looks promising, with continuous advancements in material science. New formulations of TPE are being developed to enhance the performance and sustainability of data cables. These innovations will likely lead to even more durable, efficient, and eco-friendly cables.

Integration with Emerging Technologies

As technology evolves, TPE injection data cables will integrate with emerging technologies such as 5G, the Internet of Things (IoT), and advanced automotive systems. The adaptability of TPE materials will play a crucial role in meeting the demands of these high-tech applications.

Sustainability and Eco-Friendliness

Sustainability will continue to be a significant focus for TPE injection data cable companies. The shift towards more environmentally friendly practices and materials will drive the development of cables that not only perform well but also minimize environmental impact.

Conclusion

In summary, a TPE injection data cable company stands out for its ability to produce high-quality, durable, and eco-friendly data cables. From the versatility of TPE material to the precision of injection molding, these companies leverage advanced technology and innovation to deliver superior products. Whether for consumer electronics, industrial applications, or the automotive industry, TPE injection data cables are a reliable choice for modern connectivity needs.

As we look to the future, the continuous advancements in material science and technology promise even greater developments in the field of data cables. By choosing a reputable TPE injection data cable company, you ensure that you are investing in products that are not only top-notch in performance but also aligned with sustainable practices. The future of connectivity is bright, and TPE injection data cables are poised to play a significant role in this exciting journey.

Choosing the right company is crucial for anyone looking to stay ahead in the tech game. Their dedication to quality, innovation, and sustainability makes them the ideal partner for all your connectivity needs.